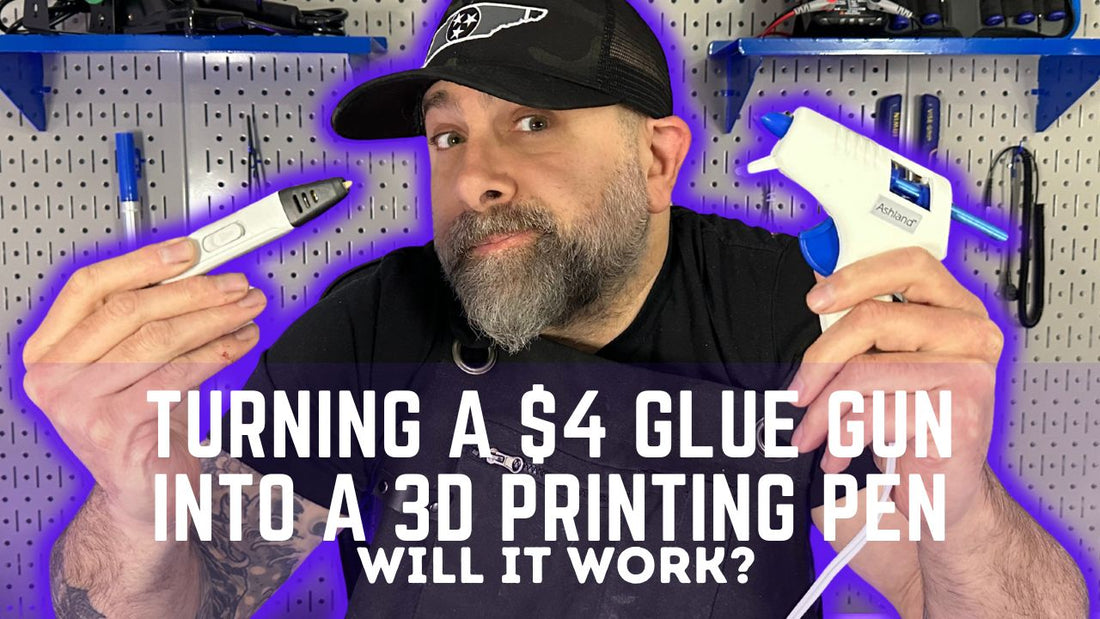

The quest for innovative and cost-effective solutions to complex problems is a constant in DIY and maker culture. Bryan DeLuca, of the Maker Build It channel, embarked on an ambitious project to create a DIY 3D printing pen for less than $4, a venture that combines ingenuity with the spirit of making.

The project kicked off with a simple yet bold idea: to repurpose a $3 hot glue gun purchased from Michaels into a functioning 3D printing pen. The initial step involved measuring standard glue sticks, which were found to be seven millimeters in diameter and 10.1 centimeters in length. These dimensions served as a benchmark for creating PLA glue sticks.

The Importance of 3D Printing Pens

3D printing pens, devices that allow users to draw three-dimensional objects in mid-air, are more than just tools for creativity. They hold significant educational value, especially in STEM (Science, Technology, Engineering, and Mathematics) fields, by making learning interactive and fostering design thinking. Beyond education, 3D printing pens offer artists a new medium to explore and are practical for designers and inventors in prototyping and small-scale manufacturing.

Trials and Tribulations

The journey was marked by experimentation and learning. Initial attempts to use the PLA sticks with the low-temperature hot glue gun did not yield the desired results. The PLA did not melt adequately, leading to the realization that a high-temperature glue gun was necessary for the task.

Switching to a high-temperature model, Bryan continued his experiments with different types of glue guns, including mini versions for their cost-effectiveness and closer resemblance to the size of a pen. Despite various attempts with different glue guns and adjustments in PLA stick densities and infills, the project faced hurdles. The primary challenge was achieving the correct temperature and pressure to extrude the PLA through the nozzle effectively.

The experiment highlighted several key insights. First, while it is theoretically possible to convert a hot glue gun into a 3D printing pen, practical challenges such as achieving the right temperature and nozzle design make it a daunting task. Bryan's experiment also underlined the importance of failure in the process of making and engineering. Each setback provided valuable lessons and opened new avenues for exploration.

Bryan DeLuca's attempt to create a DIY 3D printing pen for under $4 was a testament to the maker spirit—embracing challenges, learning from failures, and continuously exploring new possibilities. While the project did not result in a fully functional 3D printing pen, it offered insights into the complexities of DIY 3D printing technology and inspired further experimentation in the maker community.

The experiment may not have been a total success, but it underscored the importance of persistence, experimentation, and the relentless pursuit of creative solutions.

Remember, the journey of making is filled with trials and errors, and as Bryan DeLuca reminds us, "keep on making."